Coating & Services

- Polycarbonate_HC+High Abrasion Resistance Coating

- Acrylic_HC+High Abrasion Resistance Coating

- Carbon Fiber_Scratch and Abrasion Resistance Coating

- Polycarbonate_Non Sparkle AG Coating

- Acrylic_Non Sparkle AG Coating

- Polycarbonate_Anti-Foggy Coating

- Anti-Reflection Coating of PC & PMMA

- Hydrophobic_Anti-Smudge Coating

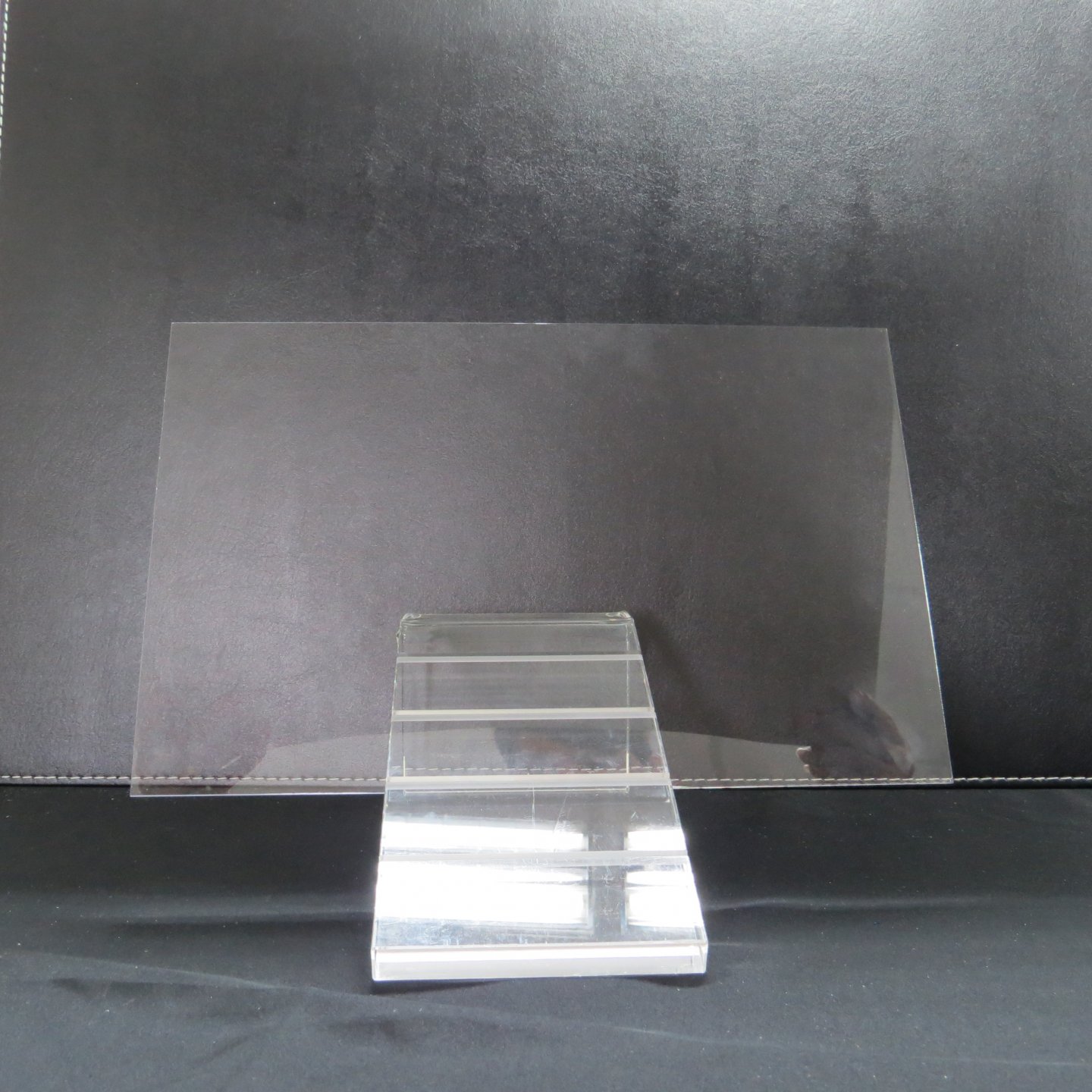

Flatness

Flatness Curved

Curved 左右尚有資訊

左右尚有資訊| Substrate | PMMA+PC+PMMA | |||

| Thickness | 1.0/2.0mm | |||

| Model Name | PHG-3L | |||

| Optical | Transmission | 91.5% | ||

| b* value | ≦0.5 | |||

| Birefringence | Visual inspection by naked eyes | None | ||

| Haze | Haze Meter | 1~10%(option)* | ||

| Surface Hardness | Pencil hardness testing by1000g loading weight. | 5~6H | ||

| Wear Resistance | S.W.#0000/45mm,45cycles/min. ΔHaze<1.5% |

500g | ~5000 cycles | |

| 1Kg | ~2000 cycles | |||

| Adhesion | 3M#610 tape test, Cross Cut | 5B | ||

| Boiling Water | 90°C/2hrs boil water tested, make the adhesion test. | 5B | ||

| Chemical Resistance |

Detergent | 25±2℃ / 65%RH 24hrs |

PASS | |

| Ethanol | ||||

| HCL 5% | ||||

| Acetone | ||||

| Ethyl Alcohol | ||||

| NaOH (PH 10) | ||||

| Reliability | 85°C, 85%RH | 1000hrs | PASS | |

| -40°C ~ +65°C | 100cycles | PASS | ||

| Printing | Printable | |||

| Shape | Flatness, Curved, Columnar | |||

Note: The above values are test reference a value, the official data is subject to the official specifications, and Colitech reserves the right to modify without permission of users.

(*) symbol means the criteria that can be adjusted according to customer needs.