Coating & Services

- Polycarbonate_HC+High Abrasion Resistance Coating

- Acrylic_HC+High Abrasion Resistance Coating

- Carbon Fiber_Scratch and Abrasion Resistance Coating

- Polycarbonate_Non Sparkle AG Coating

- Acrylic_Non Sparkle AG Coating

- Polycarbonate_Anti-Foggy Coating

- Anti-Reflection Coating of PC & PMMA

- Hydrophobic_Anti-Smudge Coating

High hardness and wear resistance coating of polycarbonate material.

Features

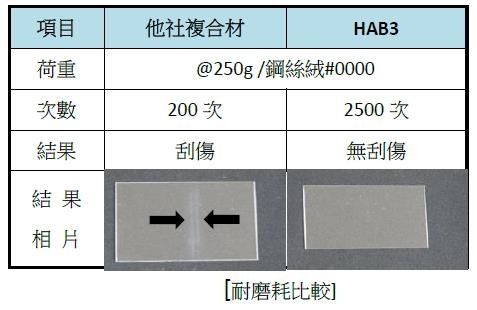

The PGP coating is applied for pure polycarbonate material, it can achieve 3H pencil high hardness and wear resistance by #0000 steel wool performance, the coating thickness control is 10~20um around, and it can shows excellent optical characteristics and improve the weakness of hardness and wear resistance,excellent optical performance design and effective, it’s without birefringence rainbow problem, and also can be combined with AR and AG related functional optical coating design.

This coating is suitable apply for touch panel, display panel of vehicle, billboards, window cover, and PC wall of building…etc.,In terms of product shape, flatness ,curved or columnar all can be processed.

Flatness

Flatness Curved

Curved Cylinder

Cylinder

左右尚有資訊

左右尚有資訊| Substrate | Polycarbonate (PC) | |||

| Thickness | 0.5~15mm | |||

| Model Name | 100: single side coating ,200:Both Sides coating | PGP-100/PGP-200 | ||

| Optical | Transmission | 91~91.5% | ||

| b* value | ≦0.5 | |||

| Birefringence | Visual inspection by naked eyes | None | ||

| Haze | Haze Meter | <0.5 | ||

| Surface Hardness | Pencil hardness testing by750g loading weight. | 2~3H | ||

| Wear Resistance | S.W.#0000/45mm,45cycles/min. ΔHaze<1.5% |

500g | ~5000 cycles | |

| 1Kg | ~2000 cycles | |||

| Adhesion | 3M#610 tape test, Cross Cut | 5B | ||

| Boiling Water | 90°C/2hrs boil water tested, make the adhesion test. | 5B | ||

| Chemical Resistance | Detergent | 25±2℃ 65%RH/ 24hrs |

PASS | |

| Ethanol | ||||

| HCL 5% | ||||

| Acetone | ||||

| Ethyl Alcohol | ||||

| NaOH (PH 10) | ||||

| Reliability |

60°C, 90%RH | 1000hrs | PASS | |

| 70°C | 500hrs | PASS | ||

| -20°C ~ +60°C | 100cycles | PASS | ||

| Printing | Printable | |||

| Shape | Flatness, Curved, Columnar | |||

Note: The above values are test reference values, the official data is subject to the official specifications, and Colitech reserves the right to modify without permission of users